Jwalo ka Pokello ya Element e bentšitsoeng Bokaholimo Nb Pure Niobium Metal Niobium Cube Niobium Ingot

Liparamente tsa Sehlahisoa

| Lebitso la Sehlahisoa | Ingot e hloekileng ea Niobium |

| Thepa | Motsoako o hloekileng oa niobium le niobium |

| Tekanyo | Ho ea ka kopo ea hau |

| Sehlopha | RO4200.RO4210,R04251,R04261 |

| Tshebetso | E phuthiloe ka serame, E phuthiloe ka mocheso, E ntšitsoe ka ntle |

| Tšobotsi | Ntlha ea ho qhibiliha: 2468℃ Ntlha ea ho belisa: 4744℃ |

| Kopo | E sebelisoa haholo masimong a lik'hemik'hale, lisebelisoa tsa elektroniki, lifofane le lifofane |

| Likarolo tsa Sehlahisoa | Khanyetso e Hlollang ea ho Sila |

Kereiti ea Niobium le sebopeho

| Sehlopha | ||||

| RO4200 | RO4210 | RO4251 | RO4261 | |

| Zr | 0.02 | 0.02 | 0.8~1.2 | 0.8~1.2 |

| Ta | 0.1 | 0.2 | 0.1 | 0.5 |

| Fe | 0.005 | 0.01 | 0.005 | 0.01 |

| Si | 0.005 | 0.005 | 0.005 | 0.005 |

| W | 0.03 | 0.05 | 0.03 | 0.05 |

| Ni | 0.005 | 0.005 | 0.005 | 0.005 |

| Mo | 0.010 | 0.010 | 0.010 | 0.05 |

| Hf | 0.02 | 0.02 | 0.02 | 0.02 |

| B | 0.0002 | - | 0.0002 | - |

| Al | 0.002 | 0.005 | 0.002 | 0.005 |

| Be | 0.005 | - | 0.005 | - |

| Cr | 0.002 | - | 0.002 | - |

| Co | 0.002 | - | 0.002 | - |

| Nb | Tekanyo | Tekanyo | Tekanyo | Tekanyo |

Litlhoko tsa mechini (boemo bo annealed)

| Sehlopha | Matla a ho tenyetseha δb psi (MPa), ≥ | Matla a tlhahiso δ0.2, psi (MPa), ≥ | Ho lelefatsa ka 1"/2" bolelele ba gage, %, ≥ |

| RO4200-1 RO4210-2 | 18000 (125) | 12000 (85) | 25 |

Lihlahisoa tsohle tsa Niobium lia fumaneha

| Lebitso la sehlahisoa | Sehlopha | E tloaelehileng |

| Niobium ingot | RO4200, RO4210, RO4251, R04261 | ASTM B392, 393, 394 ASTM B708, 365, 521 |

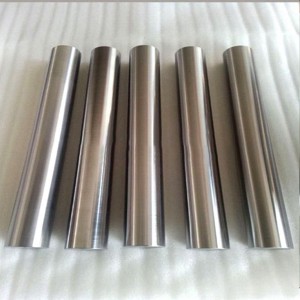

| Bara ea Niobium | ||

| Phaephe ea Niobium | ||

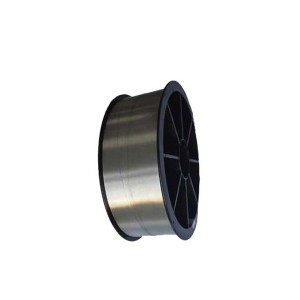

| Terata ea Niobium | ||

| Letlapa la Niobium | ||

| Sebopi sa Niobium | ||

| Sepheo sa Niobium | ||

| Likarolo tsa Niobium |

Tšobotsi

1. Kereiti: Nb1, Nb-Ti, RO4200, RO4210

2. Boholo: Bophara ba 1mm motsotso.

3. Bohloeki: 99.95%

4. Setifikeiti: ISO9001:2008, ISO14001:2004,CE

5. Sebopeho: molamu, bareng, poleiti, lakane, foil, tube, terata, crucible, jj.

6. Maemo: ASTM B392, 393, 394...

7. Ditshebediso: Disebediswa tsa semiconductor, seaparo sa vacuum, diterei tsa ho sintering le dikepe, ditshebediso tse ikgethang tsa dikhemikhale.

8. Tšobotsi ea Sehlahisoa: Sebaka se phahameng sa ho qhibiliha, ho ba le bongata bo phahameng, ho hanyetsa ho qhibiliha ha mocheso o phahameng, tšebeletso e telele, ho hanyetsa ho bola.

Kopo

1. Indasteri ea elektroniki K'hemistri, indasteri ea elektroniki, ea meriana.

2. Bakeng sa tšepe, liseramike, lisebelisoa tsa elektroniki, liindasteri tsa matla a nyutlelie le theknoloji ea superconductor;

3. Bakeng sa li-ingot tse entsoeng ka melt tse nang le conductive e ngata le li-alloying agents.

4. E sebelisoa haholo tlhahisong ea mefuta e fapaneng ea tšepe ea alloy, alloy ea mocheso o phahameng, khalase ea optical, sesebelisoa sa ho seha, lisebelisoa tsa elektroniki le thepa ea superconducting le liindasteri tse ling.