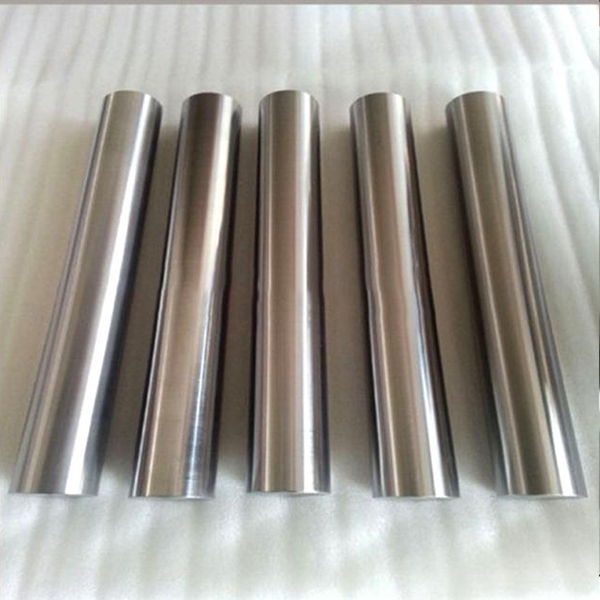

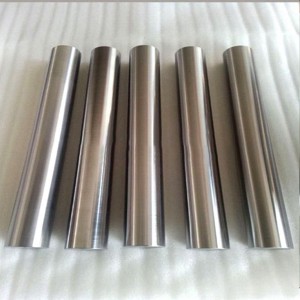

Astm B392 r04200 Type1 Nb1 99.95% Niobium Rod Pure Niobium Round Bar Theko

Liparamente tsa Sehlahisoa

| Lebitso la sehlahisoa | ASTM B392 B393 High Purity Niobium Rod Niobium Bar e nang le Theko e Molemohali |

| Bohloeki | Nb ≥99.95% |

| Sehlopha | R04200, R04210, R04251, R04261, Nb1, Nb2 |

| E tloaelehileng | ASTM B392 |

| Boholo | Boholo bo ikhethileng |

| Sebaka sa ho qhibiliha | Di-centigrade tse 2468 |

| Sebaka sa ho belisa | Dik'hilograma tse 4742 tsa centigrade |

| Molemo | ♦ Botebo bo Tlase le Matla a Phahameng a Ikhethang ♦ Ho Hanela ho Ts'enyeha ho Hlollang |

| ♦ Ho hanyetsa hantle phello ea mocheso | |

| ♦ Ha e na makenete ebile ha e na chefo | |

| ♦ Sebaka se phahameng sa ho qhibiliha, ho thibela ho bola hantle, ho tsamaisa lintho ka tsela e ntle haholo le litšobotsi tse ling tse ikhethang. |

| Sebopeho sa lik'hemik'hale (%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| Nb1 | Se setseng | 0.004 | 0.002 | 0.002 | 0.004 | 0.004 | 0.002 | 0.07 | 0.015 | 0.005 | 0.0015 | 0.003 |

| Nb2 | Se setseng | 0.02 | 0.02 | 0.005 | 0.02 | 0.02 | 0.005 | 0.15 | 0.03 | 0.01 | 0.0015 | 0.01 |

Mamello ea Tekanyo

| Bophara(mm) | Mamello ea Bophara (mm) | Bolelele (mm) | Mamello ea Bolelele (mm) |

| 3.0-4.5 | ± 0.05 | 200-1500 | +5 |

| >4.5-6.5 | ± 0.10 | 200-1500 | |

| >6.5-10.0 | ± 0.15 | 200-1500 | |

| >10-16 | ± 0.20 | 200-2000 | |

| >16-18 | ± 1.0 | 200-2000 | |

| >18-25 | ± 1.5 | 200-2000 | |

| >25-40 | ± 2.0 | 200-2000 | |

| >40-50 | ± 2.50 | 200-2000 | |

| >50-65 | ±3.00 | 200-2000 | |

| >65-150 | ±4.00 | 200-1000 |

Tlhokahalo ea Mekaniki (Boemo bo sa Lebelloang)

| Sehlopha | Matla a ho tensile δbpsi (MPa), ≥ | Matla a tlhahiso δ0.2, psi (MPa), ≥ | Ho lelefatsa bolelele ba gage ea 1"/2", %, ≥ |

| RO4200-1 RO4210-2 | 18000 (125) | 12000 (85) | 25 |

Kopo

♦ Indasteri ea elektronike, K'hemistri, ea elektronike, ea meriana.

♦ Tšepe, Liseramiki, Lisebelisoa tsa Elektroniki, liindasteri tsa matla a nyutlelie le theknoloji ea superconductor.

♦ Li-ingot tse entsoeng ka melted tse nang le conductive e ngata le metsoako ea alloying.

♦ E sebelisoa haholo tlhahisong ea mefuta e fapaneng ea tšepe ea alloy, alloy ea mocheso o phahameng, khalase ea optical, sesebelisoa sa ho seha, thepa ea superconducting le liindasteri tse ling.

Ngola molaetsa oa hau mona 'me u o romelle ho rona